The punch press is designed with direct drive servo motors, which improves die life, and reduces noise during running. In addition, the costs for wear parts and maintenance are greatly reduced. This servo-driven stamping press comes with PLC control system and HMI, ensuring the fault can be automatically identified and displayed on the screen in a real-time manner.

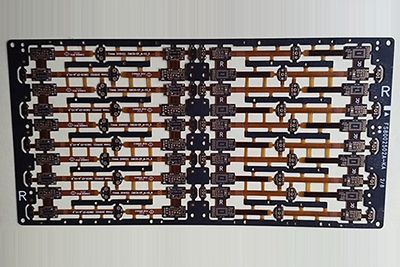

The high precision punch press is widely used in the FPC and printing industry, which meets the requirements of dust-free workshops and can be paired with automatic assembly lines.

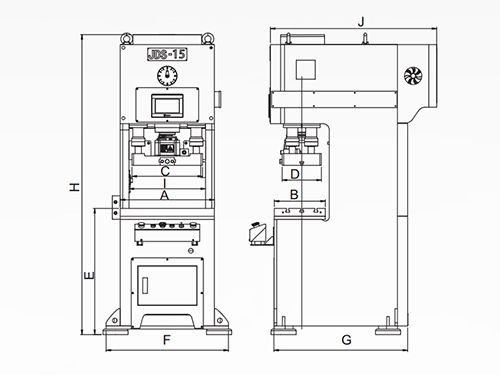

Overall dimensions

| Specification | JDS-10 | JDS-15 | JDS-25 |

| A | 600 | 600 | 600 |

| B | 300 | 300 | 300 |

| C | 450 | 450 | 450 |

| D | 250 | 250 | 250 |

| E | 805 | 805 | 805 |

| F | 780 | 780 | 780 |

| G | 875 | 875 | 875 |

| H | 1940 | 1940 | 1940 |

| I | 488 | 488 | 488 |

| J | 1060 | 1060 | 1060 |

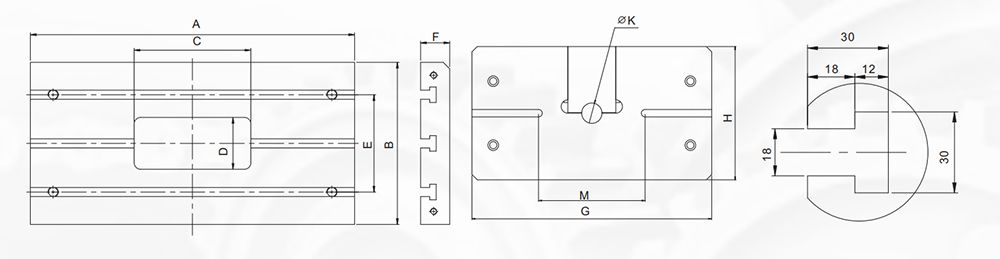

Bolster area

| Specification | A | B | C | D | E | F | G | H | M | X |

| JDS-10 | 600 | 300 | 120 | 100 | 180 | 50 | 450 | 250 | 200 | 38.1 |

| JDS-15 | 600 | 300 | 120 | 100 | 180 | 50 | 450 | 250 | 200 | 38.1 |

| JDS-25 | 650 | 300 | 120 | 100 | 180 | 65 | 450 | 250 | 200 | 38.1 |

Servo Press, No. JDS-10 Inquiry

| Model | Unit | JDS-10 | |

| Capacity | ton | 10 | |

| Stroke | mm | 50 | 80 |

| Strokes per minute at variable speeds | S.P.M | 20-100 | 20-100 |

| Max. Max. die height | mm | 210 | 195 |

| Slide adjustment | mm | 30 | |

| Slide area | mm | 450x250 | |

| Bolster area | mm | 600x300 | |

| Main motor | HP | 5.5 | |

| Slide adjustment mechanism | / | Manual operation | |

| Operation method | / | Hand operated | |

| Mode selections | / | Inch / single stroke / continuous | |

| Air pressure | kg/cm² | 5 | |

Servo Press, No. JDS-15 Inquiry

| Model | Unit | JDS-15 | |

| Capacity | ton | 15 | |

| Stroke | mm | 50 | 80 |

| Strokes per minute at variable speeds | S.P.M | 20-100 | 20-100 |

| Max. die height | mm | 210 | 195 |

| Slid adjustment | mm | 30 | |

| Slide area | mm | 450x250 | |

| Bolster area | mm | 600x300 | |

| Main motor | HP | 7.5 | |

| Slide adjustment mechanism | / | Manual operation | |

| Operation method | / | Hand operated | |

| Mode selection | / | Inch / single stroke / continuous | |

| Air pressure | kg/cm² | 5 | |

Servo Press, No. JDS-25 Inquiry

| Model | Unit | JDS-25 | |

| Capacity | ton | 25 | |

| Stroke | mm | 50 | 80 |

| Strokes per minute at variable speeds | S.P.M | 20-100 | 20-100 |

| Max. die height | mm | 210 | 195 |

| Slid adjustment | mm | 30 | |

| Slide area | mm | 450x250 | |

| Bolster area | mm | 600x300 | |

| Main motor | HP | 11 | |

| Slide adjustment mechanism | / | Manual operation | |

| Method of operation | / | Hand operated | |

| Mode selection | / | Inch / single stroke / continuous | |

| Air pressure | kg/cm² | 5 | |