Product description

APC Series 250 Ton Precision Metal Stamping Press adopts a multi-direction motion system, in which connecting rods are installed between double cranks and these rods are used to bear the load from two wide operation centers-ram and bolster. These designs help to prevent forward tilt – the direct cause to produce deviation. In this way, stamping's high-precision and small vibration could be well guaranteed. Therefore, the stamping press is quite suitable for multi-station precision pressing.

Product features

● High stiffness for its frame: Quality welded steel plates are adopted as the raw material of 250 - ton stamping press's frame. These plates undergo stress relieving, which allows for a high and stable presses precision.

● Precision stamping press possesses same center with its driving center, which allows for a stable and precise stamping.

● Two balancing devices are installed on our 250 –Ton precision stamping press, which allows a relatively stable operation.

● Allowable tolerance for this press machine is 0.1mm, which enables safe, convenient and reliable operation.

● After hard anodizing, grinding and other machining, our crankshaft, gears, connecting rods and other components all possess high performance in its physical and chemical properties.

● Since 250-ton precision metal stamping press is equipped with clutch, brake, double solenoid valve (controlling clutch by cutting off or putting through the air supply), overload protector, the safe and precise operation of stamping press's slides is guaranteed.

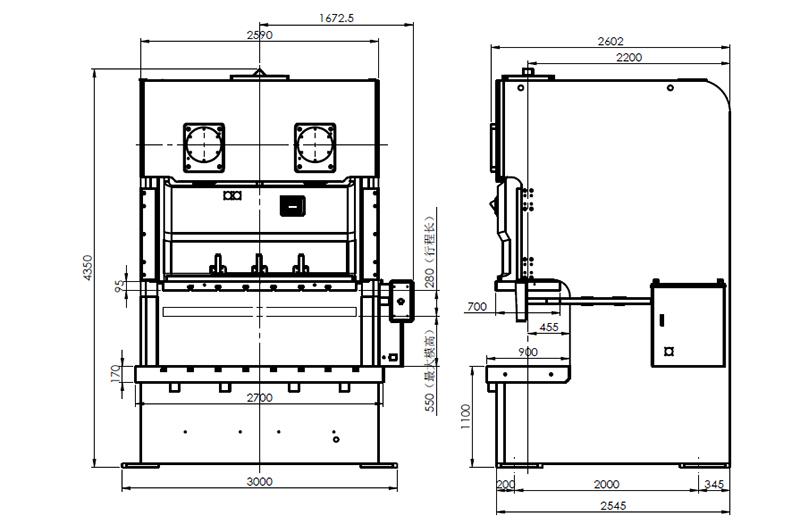

Parameters

| Name | Unit | APC-250 | |

| Model | V | H | |

| Capacity | Ton | 250 | |

| Rated tonnage point | mm | 7 | 3.5 |

| Stroke | mm | 280 | 170 |

| Stable speed | s.p.m | 20-35 | 30-60 |

| Die height | mm | 550 | 605 |

| Slide adjustment | mm | 120 | |

| Bolster area | mm | 2700X900X170 | |

| Slide area | mm | 2100X700X95 | |

| Main motor | kwxP | 22x4 | |

| Presses weight | Ton | 45.5 | |

| Air pressure | kg/cm2 | 5 | |

| Presses precision | JIS(CNS) class 1 | ||

| Die cushion capacity | Two plate & two cylinders | ||

| Capacity | Ton | 14x2 | |

| Air pressure | kg/cm2 | 6 | |

| Stroke | mm | 100 | |

| Die cushion work part dimension | mm2 | 640 x 470 x 2 | |

| Part dimension | mm2 | 540 x 350 x 2 | |

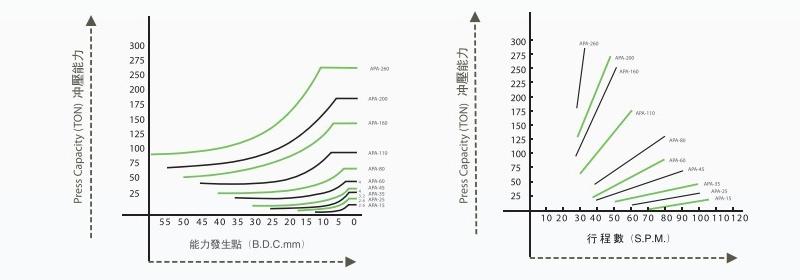

Capacity curve chart

Specification

| Model | V | H | V | H | V | H | V | H |

| AA | 2000 | 2200 | 2620 | 3000 | ||||

| AB | 1900 | 2080 | 2460 | 2800 | ||||

| AC | 1360 | 1520 | 1820 | 2200 | ||||

| AD | 1800 | 2000 | 2400 | 2700 | ||||

| AE | 1510 | 1660 | 1990 | 2220 | ||||

| AF | 1400 | 1600 | 1850 | 2100 | ||||

| AG | 1780 | 1980 | 2320 | 2590 | ||||

| BA | 1745 | 1940 | 2235 | 2545 | ||||

| BB | 1295 | 1380 | 1885 | 2195 | ||||

| BC | 650 | 760 | 840 | 900 | ||||

| BD | 330 | 385 | 425 | 455 | ||||

| BE | 500 | 550 | 650 | 700 | ||||

| HA | (630) | (730) | (790) | (820) | ||||

| HB | 830 | 865 | 990 | 1025 | 1070 | 1120 | 1100 | 1155 |

| HC | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 |

| HD | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 |

| HE | 3059 | 3709 | 3849 | 4304 | ||||

| HF | 1240 | 1440 | 1570 | 1680 | ||||

| OH | 035 | 047 | 054 | 054 | ||||

Capacity curve chart

Standard configuration

- Dry clutch brake

- Standard operating system of Yiduan

- Choice/cutting/inch/safe journey/continuation of operating mode

- Oil pressure overload protection device

- Over-run safety device

- Double solenoid valve

- Misfeed detection device

- Electric slider adjusting device

- Digital molding-height indicator (unit: 0.1 mm)

- Electric butter lubricating device

- Accumulative counter (6 digits)

- Pre-determined counter (6 digits)

- Maintenance counter (6 digits)

- Life counter (6 digits)

- Electronic rotary cam switch (6 connections)

- Air-blast device 1/2" primary circuit

- Air source connector 1/2" secondary circuit

- Error inspection socket

- Power socket (only applied to single-phase 110V power)

Optional configuration

- Wet clutch brake

- Die cushion device

- Vs variable-speed motor

- Touch-screen device

- Photo-electric safety device

- Upper slider feeding device

- Main motor inversion device

- Foot switch

- Safety dog and safety latch

- T-type two-hand button operating floor

- Inspection variable connection magnetic valve

- Anti-vibration mechanical foot

- Rapid die change device

- Upper die clamper

- Lower die clamper

- Die lifter

- Mold-shift arm

- Basic bolt and soleplate

- Automatic feeder device

- Three-in-one NC straightening feeder

- NC idler wheel feeder

- Three-in-one feeder and straightening machine

- Straightening machine